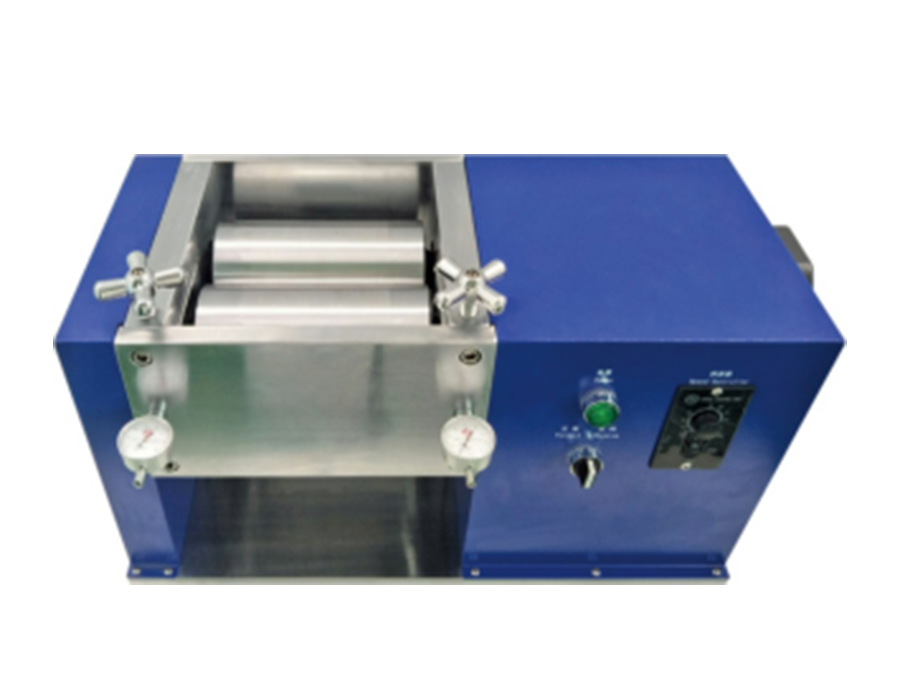

main feature:

*The roll has high hardness, and the surface is plated with hard chrome, the hardness can reach HRC62 and it is anti-rust;

*High rolling precision, roll cylindricity≤±2um;

*Adopt the inclined block to adjust the tablet gap, which has good self-locking and high adjustment accuracy;

*Horizontal design, convenient for material feeding and rolling;

*Adopt gear meshing rotation to realize roller pressing;

*The thickness and speed of tablet pressing can be adjusted, and the appearance is exquisite and beautiful;

*Electric rolling, forming automation, can be operated in forward and reverse directions;

*Small size, easy to operate, flexible and quick to use.

Technical Parameters:

* Roller diameter: 2-Φ96mm;

*Roller cylindricity: ≤±2um;

* Roller hardness: HRC62;

*Roller smoothness: above 0.4;

*Rolling thickness: 0~2mm gap can be adjusted;

* Tablet width: 0 ~ 100mm;

*Roll placement: horizontal placement;

* Tablet thickness and speed can be adjusted;

*Operation mode: electric;

* Voltage and frequency: AC220V/50Hz;

* Power: 120W;

*Feeding speed: 0~40mm/s;

* Dimensions: L500mm * W360mm * H620mm;

*Equipment weight: 50KG.

Electric roller machine

This machine is independently developed and is mainly suitable for electric rolling of battery materials in the laboratory, a small amount of precious metal materials such as gold and silver, and non-ferrous materials such as copper and aluminum. It is especially suitable for thinning and increasing density of clean energy materials lithium battery plates. This machine adopts gear transmission,