main feature:

1. Strong wind circulation drying and heating, digital display temperature control;

2. Flat-plate coating, motor-driven scraper coating, stable and adjustable coating speed;

3. The coating speed is adjustable within the range of 0-120mm/sec (lithium iron phosphate slurry);

4. Vacuum aluminum plate can quickly place or remove the substrate;

5. The stroke can be adjusted by the stroke switch between 0 and 250mm;

6. Standard film maker, high coating precision, adjustable coating thickness;

7. Can be used in the glove box, easy to operate and small in size, saving space;

8. Built-in vacuum pump, substrate adsorption without deformation and wrinkles;

9. The appearance is exquisite, and the sheet metal adopts a three-dimensional geometric design, which is simple and beautiful.

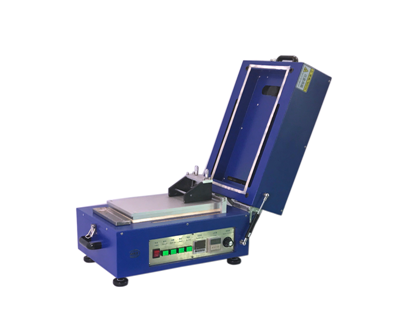

Technical Parameters:

*Coating method: Flat-plate coating, metering devices such as film maker or scraper as standard

*Coating drive: driven by motor, the coating speed is stable and adjustable

*Coating width: 100mm can be customized

* Coating speed: 0~120mm/s (lithium iron phosphate slurry);

*The stroke can be adjusted by the stroke switch between 0 and 250mm;

* Vacuum plate: with vacuum aluminum plate;

*Vacuum plate size: L365mm×W200mm×H32mm;

* Adjustable range of scraper: 0.02 ~ 3.5mm adjustable;

*Accuracy: 10um

*Heating and drying system: room temperature to 120°C, digital display temperature controller, accuracy ±1°C

*Contains 1 built-in oil-free vacuum pump;

* Power supply: 220V/50Hz;

*Dimensions: L500mm×W350mm×H320mm;

Automatic coating dryer equipment

The automatic coating dryer experimental equipment is widely used in various high-temperature coating research, such as ceramic thin films, crystal thin films, battery material thin films, and special nano thin films; it can adapt to the development of science and technology for film formation under high temperature conditions