Main feature

*The sealing head is made of copper materials,have a good heating transfer effect and power saving,can improve the work effective and more energy saving than other similar product;

*The pressure of the upper and lower sealing head can adjust by pressure regulator to achieve difference process parameter requirement;

*The upper and lower sealing head driven by cylinder and the direction controlled by two linear guide sheath.Flexible move ,accurate guide guarantee the parallelism requirement of the product after sealing.;

*With pierce function;

*Chamber lid driven by cylinder,and guide by linear sheath,flexible up and down activities,which can promise the requirement of the sealing performance;

*Can suit for difference model battery, and easy to adjust;

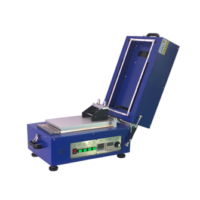

*Easy to operate,beauty appearance, small size and weight;

Technical parameter

*Chamber made by Aluminum alloy,anti corrosion,and firm structure;

*Vacuum degree≤-96Kpa(Buyer-provided vacuum pump);

*Sealing head temperature:room temperature~250℃,adjustable;

*Temperature control precision:±1.5℃;

*Heating sealing pressure:0~7Kg/cm2 adjustable;

*Heating sealing time:0~99S adjustable;

*Sealing width:5±0.4mm(according the requirement of the customer);

*Sealing length:340mm

*Maximum sealing size:310mm;

*Sealing thickness range:60~300um

*Sealing thickness precision.(mm):Package thickness difference at any two points<15um.

*Air consumption:About 0.2L compress air/time。

*Air compressor working speed:≥180 times/h

*Power:Using 500w heating tube, the power consumption when heating is about 0.6KW。

*Power:220V/50Hz;

*Compress air source:0.5~0.7Mpa;

*Dimension:L600mm*W650mm*L800mm;